Over the last couple of days I built a stir plate for making beer (well, yeast) . It was a fun project and I learned a new life skill to boot! Many of the beers I brew seem like they don't ferment as completely as they should and having a good population of healthy yeast to start fermentation is one of the biggest keys to making this happen. I decided to build one from scratch because if you were to buy one online they easily go for $50-$100+ just for a thing that spins a magnetic bar in place. So for under $30 I was able to make my own!

Yesterday I spent a few hours at home working on this, I took the day off from work because a cold had deenergized me and sitting at the table watching metal melt was actually pretty therapeutic.

So here's how I did it, Loyal followers might be bored but this post is for the internet strangers who might want to tackle this for themselves.

Part List:

Cigar Box (mine was $2 I got it from a liquor store with a cigar humidor)

Machine Screws, Nuts, Lock Nuts, Washers (you can see the sizes in the photo)

Old Computer Fan, I had a fancy LED one on hand from my out of commission PC I built in High School (I got rid of my junk part computers.)

Potentiometer

On off switch

Power Jack Socket (make sure it fits your power cable if you use an old one)

Wire

Old 12V power cable (I got rid of a bunch a few years ago so I bought a new one. Damn.)

Drill and bits

Soldering Iron with Electrical Solder

Wrench and vice grip was useful too.

|

| Parts & some tools. |

Measure and Drill. I made mine slightly off center because there is a graphic on top that I thought would make a good visual cue for knowing where the magnets were located. Experience has now taught me that was a good idea at the time but unnecessary.

|

| I couter-sunk the screw heads a little so they wouldn't stick out as far. |

Washers for stability so I don't pull only on the wood.

I had to drill out the front a little so that I could get the mounting nut onto the threads.

|

| Big hole for the On/Off Switch |

|

| An interested person could use this as a wiring diagram |

|

| This was my first time soldering anything. |

This seems like a good time to say, unlike a lot of DYI stir plates rather than hard wiring a split power cable around the inside I used a power jack. Since I'm a recent Dad I realized if the cord were to get kicked or pulled I would rather the power cord pop out than to have to re solder (or buy) a bunch of parts. For only one extra hole and two more soldier points, it wasn't much extra work, and it cost less than $1, totally worth it.

This one is tricky, you actually solder the right wire to the first two posts and the left wire just goes to the far left post.

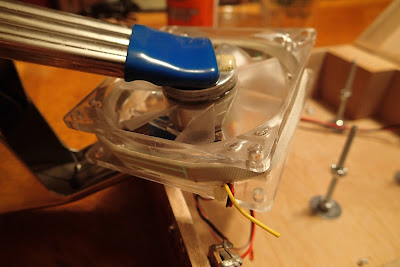

I used lock nuts to hold the fan up so it can be as close to the lid as possible. I chose lock nuts because they wont slip with constant vibration so they will stay in place when a little fan is spinning on top of them. On the bottom of the screws I used two nuts to hold the screw tight, it's a poor mans lock nut, this way I didn't need to use a wrench to get them all the way to the bottom, just to tighten.

|

| A couple of nuts on top of the fan to tighten, it works! |

I thought I read somewhere that you want some distance between your magnets and the fan to keep the fan motor from interfering with the magnets. I don't know if that's exactly why, but I had these washers around and they ended up fitting the center part of the fan perfect. This is them being glued together.

I held the magnets on the washer under the flask with the stir bar in it. You have to align the polarity of the magnets up with the stir bar so it automatically rights itself above the magnets, so the ends of the bar are attracted to the magnets, not repelled. When I first did it, one end spun away when the other stayed attracted, but when I flipped the other magnet it aligned nicely.

|

| Stupid foamy but effective Gorilla Glue. |

|

| Mounting to the fan with more glue. Clamped overnight. |

|

| My assistant, Jinx. |

The big test! It works! I had to do some tweaking with the height of the fan to get it to fit properly but afterward all was good!

My first test with water kept throwing the bar off, despite being able to spin at high speed while it was dry. After asking for some help from the homebrewing subreddit I stuck another magnet to both the glued ones to increase their strength. Which worked! I'll probably also get another smaller stir bar because it should fit between the two magnets, not beyond, this will supposedly help it spin faster to create a bigger vortex.

The puropse of the stir plate is to keep yeast in suspension and to aerate the liquid they're in to help build a nice healthy population. A bigger vortex may actually do more harm than good for the yeast. I just want to make sure my stir bar won't get thrown in the middle of the night, so if it can spin faster without getting thrown it should work just fine at a slower speed when I'm using it for it's purpose.

Final thoughts:

Soldering isn't as hard as I thought it would be, I was really dreading it, but after watching this video on YouTube I realized it wasn't so bad. I picked up a $4 soldering Iron and had some solder on hand in my old computer repair kit.

The potentiometer I got might not be the right size for my project, only about a quarter of the dial is functional before the fan just stops spinning. I don't know if it has something to do with the LEDS taking some current, I don't know how that stuff works, maybe someone more knowledgeable than me could let me know.

I might get some grippy rubber feet to stick to the bottom.

This was fun! Altogether I think I spent about 6 hours on this project.

No comments:

Post a Comment